Thickness effect - Nano-scale polymer layer thickness change can alter the drop motions and interfacial interaction

A team led by Hans-Jürgen Butt at the Max Planck Institute for Polymer Research has discovered that altering the thickness of nano-scale polymer layers, even within a range of 10 nm, can significantly influence drop motions. They found a 'magic thickness' of 5 nm for polydimethylsiloxane (PDMS) which results in the lowest interfacial friction between a sliding water drop and the PDMS layer. This finding is of great significance for promoting the application of fluoride-free nano coatings in liquid environments.

Polymers can be coated on surfaces at a nano-scale by controlling their molecular weight, thereby altering the interfacial properties of materials while preserving bulk characteristics. Through structural design, these coatings can enhance biocompatibility in medical devices, boost performance and durability in semiconductor electronics, improve efficiency in solar cells and batteries, and provide low-adhesion coatings in automotive and aerospace applications. In most of these applications, the coating needs to be effective in a liquid environment. Thus, the interaction between the liquid and the polymer surface should be considered.

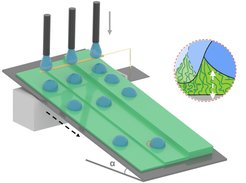

The interaction between the same liquid and a surface is typically considered to depend on the bulk properties of the surface coating and the charges or defects generated by the drop moving along the surface in a dynamic process. However, the team at MPI-P has found that altering the thickness of a nano-scale polymer layer can significantly affect the liquid-polymer interfacial friction. This was demonstrated by sliding water drops on a series of PDMS samples on non-chargeable substrates, revealing that the thickness parameter plays a crucial role in the interfacial dynamics.

"We were inspired by previous studies reporting that static contact angle hysteresis changes with PDMS thickness. By eliminating the charge effect, we surprisingly discovered new mechanisms related to thickness that also govern the dynamic drop sliding process," says Hans-Jürgen Butt, Director of the "Physics at Interfaces" department at the MPI-P.

In a new article published in the journal "Advanced Materials," Hans-Jürgen Butt and his colleagues have demonstrated that thickness can be a reliable predictor of drop velocity on nano-scale polymer coatings. Several interfacial interactions, observed through molecular-level measurements, exhibit similar trends as friction changes with thickness. They attribute this to the nano-scale thickness, which is comparable to the interface thickness, and the inherent flexibility of the polymer. These factors alter the arrangement of the interface due to varying Van der Waals forces, which affect the stabilization of the interfaces in this system. Additionally, due to the high flexibility of the polymer, the formation of a capillary ridge must also be considered once a critical thickness is reached.

With their work, the scientists aim to address the challenges engineers encounter when fabricating nano coatings from polymers. This research could also assist the industry in utilizing an easily measurable parameter to rapidly control the quality of millions of nano coatings produced every day.

Does this thickness effect also occur in other types of polymer layers, and what does the actual liquid-polymer interface look like at the nano-scale? These and other questions remain to be explored in future scientific investigations.